Technical ceramics, also known as advanced ceramics, have become integral to numerous industries due to their exceptional properties and versatility. These materials are engineered to meet specific requirements that conventional ceramics and metals cannot, making them invaluable in modern technology and manufacturing. This article explores the remarkable benefits, applications, and innovations in alumina ceramic.

What Are Technical Ceramics?

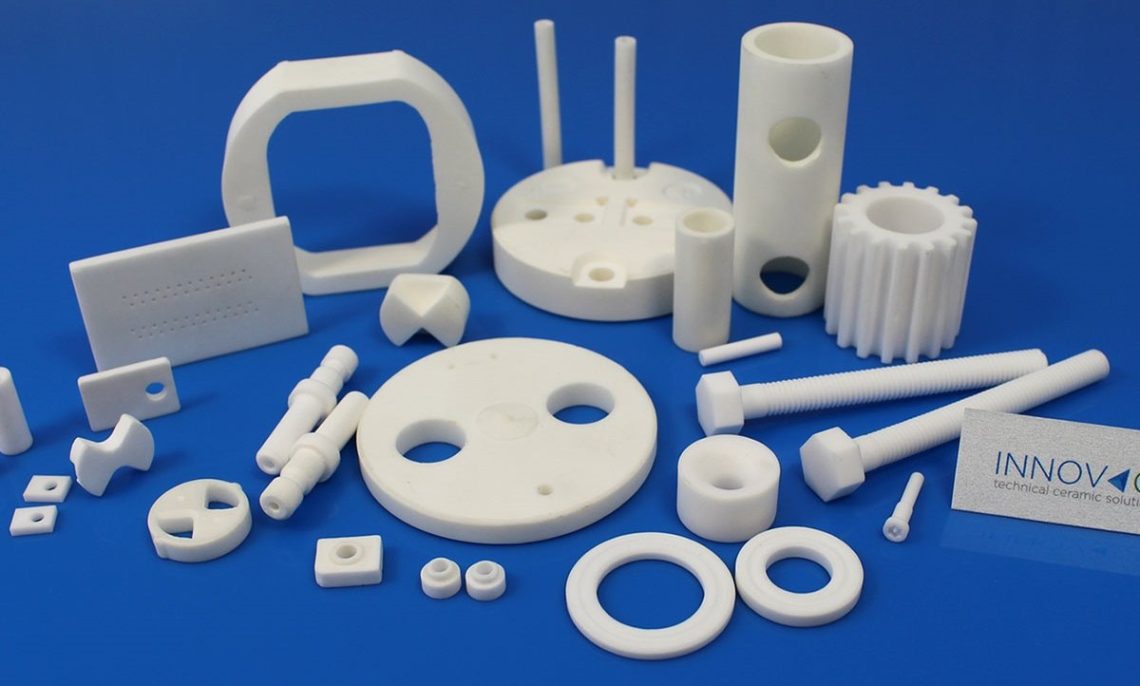

Technical ceramics are materials made from inorganic, non-metallic compounds, primarily oxides, carbides, nitrides, and borides. Unlike traditional ceramics, which are often used for decorative or utilitarian purposes, technical ceramics are designed for high-performance applications. They exhibit superior mechanical strength, hardness, wear resistance, and thermal stability, making them suitable for demanding environments.

Key Properties of Technical Ceramics

- High Hardness and Wear Resistance: Technical ceramics are renowned for their hardness and resistance to abrasion. This makes them ideal for components subjected to intense wear and tear, such as cutting tools and bearings.

- Thermal Stability: These materials can withstand extreme temperatures without losing their structural integrity, which is crucial for applications in aerospace, automotive, and electronics.

- Chemical Resistance: Technical ceramics are highly resistant to corrosive substances, making them suitable for use in harsh chemical environments.

- Electrical Insulation: Many technical ceramics possess excellent insulating properties, which are vital for electronic and electrical applications.

- Biocompatibility: Certain advanced ceramics are biocompatible, meaning they can safely interact with biological systems, making them valuable in medical implants and devices.

Applications of Technical Ceramics

- Aerospace and Defense: In the aerospace industry, technical ceramics are used in turbine engines, spacecraft components, and armor materials. Their ability to withstand high temperatures and corrosive environments makes them indispensable for these high-stakes applications.

- Electronics: Technical ceramics are crucial in the electronics sector for components such as capacitors, insulators, and substrates. Their electrical insulating properties ensure the reliable operation of electronic devices and circuits.

- Automotive: In automotive engineering, technical ceramics are used in spark plugs, catalytic converters, and wear-resistant coatings. They enhance performance and longevity while reducing emissions.

- Medical Devices: Biocompatible ceramics are employed in medical implants, dental prosthetics, and surgical instruments. Their compatibility with human tissue ensures safety and effectiveness in medical applications.

- Industrial Equipment: Technical ceramics are utilized in various industrial processes, including cutting tools, grinding media, and wear-resistant linings. They improve efficiency and durability in manufacturing operations.

Innovations and Future Trends

The field of technical ceramics is constantly evolving, driven by advancements in material science and engineering. Some notable trends include:

- Nanotechnology: Incorporating nanomaterials into technical ceramics enhances their properties, such as strength, thermal conductivity, and electrical performance. Nanotechnology is paving the way for more advanced and efficient ceramic solutions.

- Additive Manufacturing: 3D printing technologies are being used to create complex ceramic components with high precision. This innovation allows for the production of custom parts and reduces waste in the manufacturing process.

- Hybrid Materials: Combining technical ceramics with other materials, such as metals or polymers, creates hybrid materials with tailored properties. These composites offer enhanced performance for specific applications.

- Sustainability: There is a growing focus on developing eco-friendly ceramics and manufacturing processes. Sustainable practices aim to reduce environmental impact and promote the use of recycled materials.

Technical ceramics represent a significant advancement in materials science, offering unparalleled performance and reliability across a wide range of industries. Their unique properties enable innovations that drive progress in aerospace, electronics, automotive, medical devices, and industrial applications.